Coming to types of conveyors, there are many alternative varieties of conveyors we are able to notice. First of all companies those who want to use conveyors should be able to notice their wants. Some of the foremost common things ought to be considered before installation are mentioned below.

- Product type being handled: Unit load or Bulk load

- Product dimension: Length, breadth and height

- Product Variability

- Surrounding environment i.e., It's location : Overhead, on-floor, or in-floor

- Whether or not lots will accumulate on the conveyor

- Type of path: Horizontal, Declined or Inclined manner

Different types of conveyors:

The verity of conveyors is infinite, but the two major classifications used in typical plants are Pneumatic and Mechanical.

Note: The power requirement of a Pneumatic conveyor system are much greater than for a mechanical conveyor of equal capacity.

Mechanical Conveyors:

a. Gravity Roller conveyor

b. Live powered roller conveyor

a. Magnetic belt conveyor

b. Troughed belt conveyor

c. Slider bed

d. Roller bed

e. Horizontal belt conveyor

i. Portable conveyor

7. Bucket conveyor

8. Vibrating conveyor

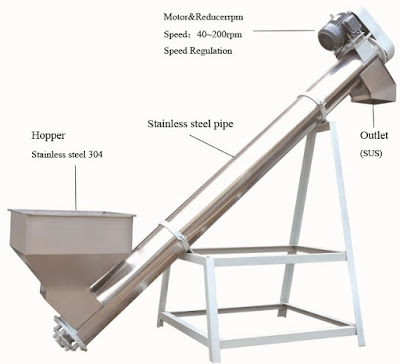

9. Screw conveyor

10. Tow conveyor

11. Trolley conveyor

12. Monorail conveyor

Pneumatic Conveyors: